Termékleírás

Shark 281 NC 5.0, electrohydraulic automatic band sawing machine which can operate also in semi-automatic, semi-automatic/dynamic and manual mode to cut from 0° to 60° left.

– CNC machine with a new controller : MEP 50 with Windows “CE” based. This new PLC has been specifically designed by MEP for the automation of its range of products.

A FEW FEATURES:

-7” touch screen display operator interface and push buttons for all functions of the sawing machine. It is simple and intuitive , it guarantees a reliable use and it controls all cutting parameters in real time.

– Console with all centralized controls, installed on an articulated arm to follow the operator in every operating position for the controls and the EMERGENCY.

– Visualization and registration of alarms and events with the possibility to visualize the story of occurred events.

– Electronic inverter for the continuous adjustment of the band speed from 15 to 100 m/min.

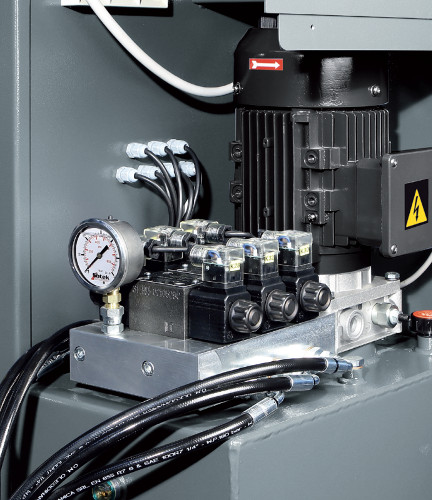

– Latest generation hydraulic control unit, with high efficiency and low energy consumption.

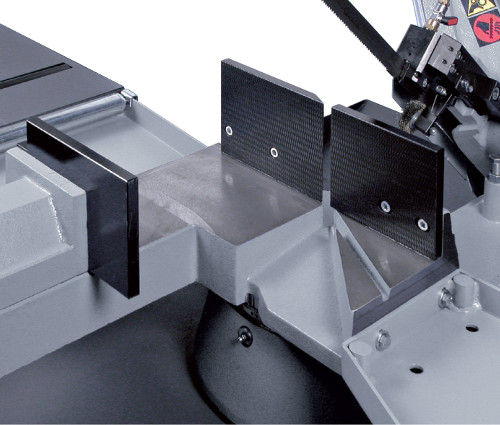

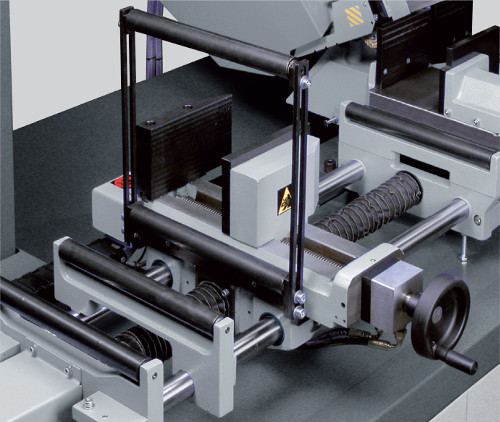

– Bar feeder with recirculating balls screw/nut and stepper motor (feed in length in one stroke 600 mm, that can be repeated in order to cut any length).

– Cutting head and feeding vice positioning with joystick

– Automatic acquisition of the actual starting point of the cut.

– Electronic transducer to visualize band tensioning.

– Automatic adaptive shearing stress control system with servovalve mounted directly on the cylinder.

– Coolant tank inside the steel base with two electric pumps so as to lubro-refrigerate band. The drawer to collect chips can be replaced with a motorized chip evacuator (see optionals).

– Preset to be equipped with the spray mist system (OPTIONAL), as well as with the standard-delivered traditional lubrication with emulsible oil.

– Wire chip brush for band cleaning.

– Machine arranged for handling with movement equipment.

– Bi-metal band for solids and sections.

– Service keys and instructions manual for maintenance and spare parts list.

FEATURED SPECIFICATIONS: