Leírás

TIGER 352 NC 5.0, electro-pneumatic automatic vertical sawing machine which can operate also in semi-auto- matic mode, to cut from 60° left to 45° right, with HSS blade.

-CNC machine with a new controller : MEP 50 with Windows “CE” based. This new PLC has been specifically designed by MEP for the automation of its range of products.

A FEW FEATURES:

– 7” touch screen display operator interface and push buttons for all functions of the sawing machine. It is simple and intuitive , it guarantees a reliable use and it controls all cutting parameters in real time

– Console with all centralized controls, installed on an articulated arm to follow the operator in every operating position for the controls and the EMERGENCY.

– Registration of alarms and events with the possibility to visualize the story of occurred events.

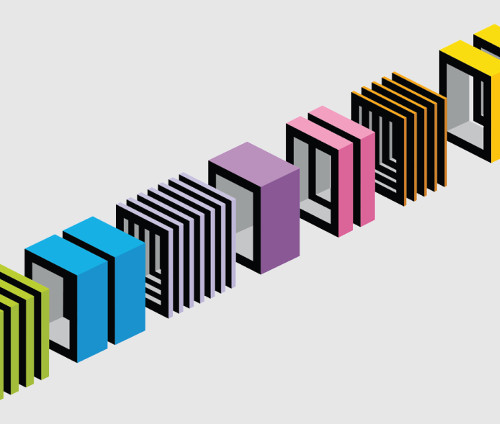

– Bar feeder with recirculating balls screw/nut and stepper motor (feed in length in one stroke 600 mm, that can be repeated in order to cut any length).

– Electronic inverter for the continuous adjustment of the band speed from 15 to 90 rpm (OPTIONAL 30 to 150 rpm).

– Panel with low tension controls: polyester membrane keypad with tactile thermo-shaped buttons which give out an acoustic signal when pressed.

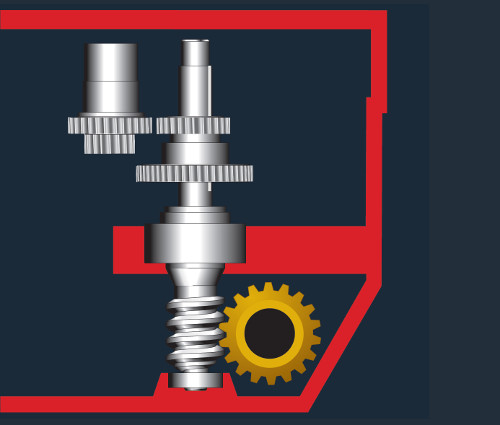

– Double set of gears to obtain a high performance.

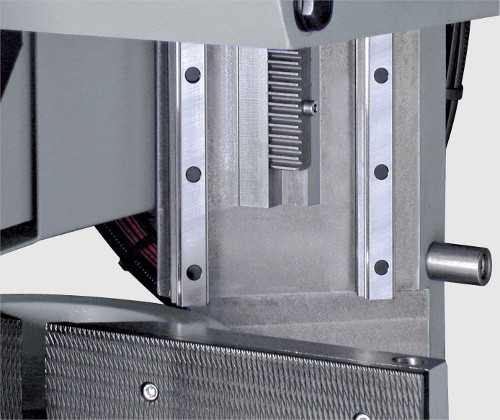

– Sawing head movement on double linear guides with preloaded slides with recirculating ballscrews.

– Coaxial cylinder with bypass valve for fast approach and linear transducer for head position reading.

– Cutting head and feeding vice positioning with joystick

– Automatic acquisition of the actual starting point of the cut

– Shearing stress control.

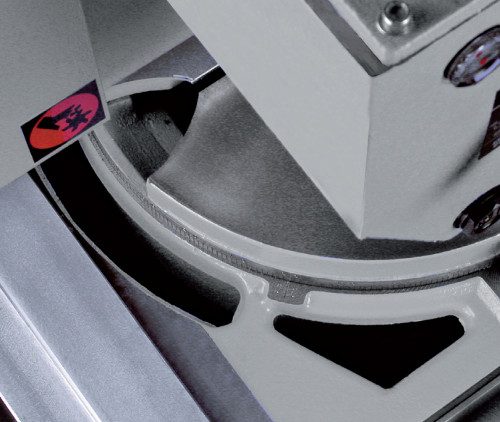

– Rotating table on a center pin with axial bearing which allows higher precision on the cutting angle set.

– Pneumatic vertical vice.

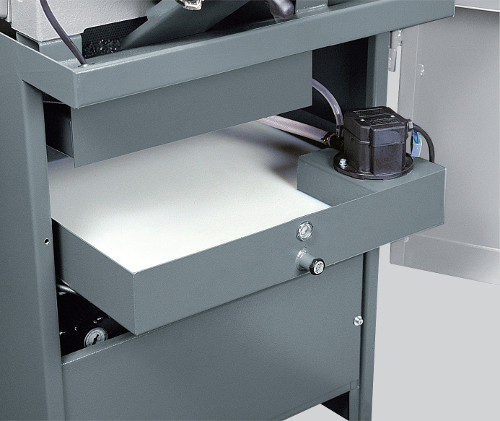

– Electric pump for the blade lubrication and cooling.

– Wire chip brush for band cleaning.

– Indicator with flashing light in case cycle is stopped.

– HSS blade Ø 350x32x2.5 for solids or sections.

– Preset to be equipped with the spray mist system (OPTIONAL), as well as with the standard-delivered traditio- nal lubrication with emulsible oil.

– Service keys and instructions manual for maintenance and spare parts list.

FEATURED SPECIFICATIONS: